Medical Devices Testing

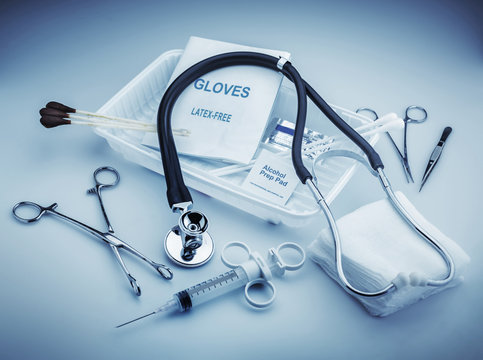

Medical accessories play a crucial role in the healthcare industry, aiding in diagnosis, treatment, and patient care. Ensuring their optimal performance and safety is essential to maintain the highest standards of healthcare delivery.

Importance of Testing:

- Patient Safety: Medical accessories directly interact with patients, and any malfunction or failure could lead to adverse effects on their health. Testing helps identify potential risks and ensures patient safety by detecting flaws early in the development process.

- Performance Optimization: Thorough testing enables manufacturers to fine-tune and optimize the performance of medical accessories, ensuring accurate and reliable results. This improves diagnostic capabilities, treatment efficacy, and overall patient outcomes.

- Regulatory Compliance: Regulatory bodies, such as the FDA (Food and Drug Administration) in the United States, require medical accessories to undergo rigorous testing to meet quality and safety standards. Compliance with these regulations is necessary for market approval and maintaining public trust.

Key Aspects of Testing :

- Functional Testing: Assessing the functionality of medical accessories involves verifying if they perform their intended purpose accurately. This includes evaluating parameters such as accuracy, precision, sensitivity, specificity, and response time.

- Durability and Reliability: Testing for durability ensures that medical accessories can withstand the intended usage environment and maintain performance over time. Reliability testing involves assessing the device's ability to consistently function without failure or errors.

- Compatibility Testing: Medical accessories often interact with other devices, such as monitoring systems or electronic health records. Compatibility testing ensures seamless integration and interoperability, preventing data loss or communication issues.

- Safety and Biocompatibility: Testing for safety involves evaluating potential risks, such as electrical hazards, sharp edges, or toxic materials. Biocompatibility testing ensures that materials used in medical accessories do not cause adverse reactions or harm to patients.

- Sterilization and Cleaning Validation: Medical accessories that come into contact with patients or bodily fluids must be effectively sterilized and cleaned. Validating the sterilization and cleaning processes ensures the removal of contaminants and the prevention of infection transmission.

- Usability Testing: Evaluating the ease of use and user interface design of medical accessories is vital for healthcare professionals. Usability testing helps identify potential user errors, provides feedback for design improvements, and ensures efficient and intuitive operation.